If you’re comparing drivers in detail, it will help to understand some of the more intricate TS Parameters, as over time it will help you differentiate between different drivers and identify which applications they are more suited for.

For example, for a high power 18″ horn loaded bass bin, you will probably be looking for a driver with a high BL, and a strong, rigid cone. A strong cone will generally also be a heavier cone, so you’ll be looking for a driver with a heavier cone. Lightweight cones have been used in horn loaded bass bins, but usually for lower powered applications focusing on upper bass .

For a 12″ midrange driver focused on vocal reproduction, a lighter cone (lower Mms) improves transient response and accuracy.

Mmd is the mass of the moving parts of the driver; the diaphragm, dust dome and voice coil. The diaphragm is the paper cone in a standard speaker. The voice coil includes the former and the copper wire. Most definitions online for Mmd seem to just be copies of each other, citing that the surround and spider are included in the moving mass. A bit of further research has suggested that only part of the mass of the spider and surround should be included, as the outside edge of the surround, and the outside edge of the spider are both glued to the chassis, and therefore DO NOT MOVE.

Mms is commonly used in loudspeaker modelling software. It is Mmd plus the ‘air load’. The air load is the air just in front, and just behind the speaker cone that will tend to move back and forth with the cone. It’s just a few grams of air, but for mathematical modelling of speaker performance, needs to be added in. A larger cone will have a larger air load.

Mms is used to calculate other important TS Parameters, such as Qes and Qms which can not be measured directly.

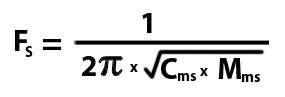

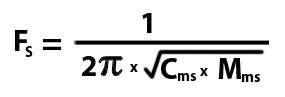

There is one final significant point with regard to the Mms, and that is the relationship to Fs (Free Air resonance). Mms directly affects Fs (free-air resonance). A heavier cone lowers Fs, while a lighter cone raises it. Fs is also influenced by Cms, the compliance of the suspension. The formula which connects Fs to Mms is as follows:

Click here to read more about Thiele Small Parameters: Fs (Free Air Resonance)

As with all Thiele-Small parameters, Mms interacts with other factors like BL, Cms, and cone stiffness. The fact that cone weight, voice coil geometry, magnet strength, cone stiffness all interact and affect each other in both positive and negative ways means that any speaker design always has some compromises. Some might call this optimisation – a driver specifically designed for the best sub-bass response will sacrifice mid and upper bass response.

Lower bass frequencies require a heavier, stiffer cone. However, increasing Mms reduces efficiency, which must be countered with a stronger magnet and a longer voice coil to maintain performance.. Its unsurprising that in many instances, a compromise is settled on, which balances efficiency, resonant frequency, and cost.

For better midrange response, reducing Mms improves accuracy but raises Fs. This works well for midrange drivers but is undesirable for mid-bass woofers. As with most things in life, you can’t have your cake and eat it too. The only way to effectively cover the full frequency range is to use different drivers optimized for specific tasks