The resonant frequency (Fs) is the frequency at which a speaker cone and voice coil naturally oscillate with minimal resistance. At this frequency, the driver moves more easily, requiring less energy to reach high excursion. Ever seen that famous footage of a bridge wobbling like jelly before collapsing? That’s a classic example of resonance in action! Just like that bridge, a speaker cone naturally vibrates most at its resonant frequency, take a look here to see the power of resonance: http://www.youtube.com/watch?v=j-zczJXSxnw

The resonant frequency is influenced by the weight of the cone and voice coil (sometimes referred to as the moving mass) and the stiffness of the parts that return the cone to it’s central natural rest position. If you apply a sine wave to a speaker outside of a cabinet, its cone will move much more at Fs than at other frequencies. This is because, at resonance, the balance of cone weight and suspension stiffness offers the least resistance to movement, allowing for largest excursions.

Just like the bridge, a speaker can suffer damage if pushed too hard at its resonant frequency. This is why many designs recommend using a High-Pass Filter (HPF) just below Fs to prevent excessive excursion and protect the driver. Cabinet design affects the HPF recommendation. In bass reflex systems, the port tuning reduces cone excursion at Fs but allows increased excursion below Fs, making an HPF even more important. The purpose of the HPF is to keep the driver operating within a frequency range that does not allow excessive excursion – without the HPF it is possible to damage your speakers through excursion without exceeding the power handling capacity of the speaker. However, if you set the HPF incorrectly, it is possible to reduce excursion too much, and since most woofers rely on the movement of the cone to push air through the voice coil vents, you do need to maintain excursion to keep air moving.

As a general rule, most drivers struggle to produce sound effectively at frequencies significantly below their Fs. Using a gentle HPF near the driver’s resonant frequency is a good way to stop your drivers being ripped apart from over-excursion. There are exceptions of course, if you have a high power woofer, that you plan to use a lower power levels, well within its working limits for a home cinema application, you may not want the HPF, as you want to reproduce those low frequencies for the full cinema experience. Since you wont be pushing them to maximum power, lower efficiency is less critical, and then chance of damage is reduced.

A driver with an Fs of 50Hz won’t be effective for deep sub-bass at 30Hz. For subwoofer applications, a driver with an Fs of around 30Hz or lower is ideal, provided the cabinet design supports it.

However, if you are replacing an existing driver in a Ported Bass Reflex cabinet (one of the most common types), it’s generally a good idea to choose a replacement with a similar resonant frequency. The original speaker cabinet would have been tuned to match the driver, and putting in a significantly different driver will result in a mismatch, resulting in less than optimal performance, which in serious cases can result in premature failure of a driver due to over-excursion.

For serious sub-bass applications, the lower the Fs, the better. For mid-range, the resonant frequency of a cone driver is often irrelevant, as the operating frequency range will usually be significantly higher than the resonant frequency.

For compression drivers, Fs is crucial. A typical 1” exit compression driver has an Fs of 500-600Hz, but the recommended minimum operating frequency is typically one octave above Fs (1000-1200Hz). This ensures safe operation with minimal excursion. At Fs, a compression driver’s diaphragm moves excessively, which can be catastrophic. If excursion is too high, the diaphragm may hit the phase plug, causing it to shatter. Keeping an octave above the resonant frequency ensures the compression driver’s diaphragm stays within relatively low excursion limits.

It’s possible to damage compression driver diaphragms with bass and mid frequencies quite easily, it is for this reason that it’s common to put in a 1st order high pass filter ( a single capacitor) in series with a compression driver when it is used in an active system. This protects against accidental erroneous connection to the wrong amplifier, and it’s good practice to do this if your system has numerous connectors which look similar.

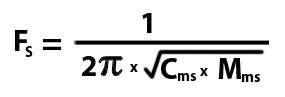

Once you start looking at the Thiele Small Parameters, you will start to become aware that speaker parameters all interact. The formula which for Fs is as follows:

Cms is a measure of the suspension (surround and spider) compliance. Compliance is the inverse of stiffness. High stiffness is low compliance. Low stiffness is high compliance. Stiffer suspension will make the resonant frequency higher, looser suspension will make the resonant frequency lower.

Mms is the mass of the moving parts of the driver, including ‘air load’. A heavier cone will have a lower resonant frequency, and a lighter cone will have a higher resonant frequency.

You can read more about Mms here: https://speakerwizard.co.uk/driver-ts-parameters-mmd-mms/.