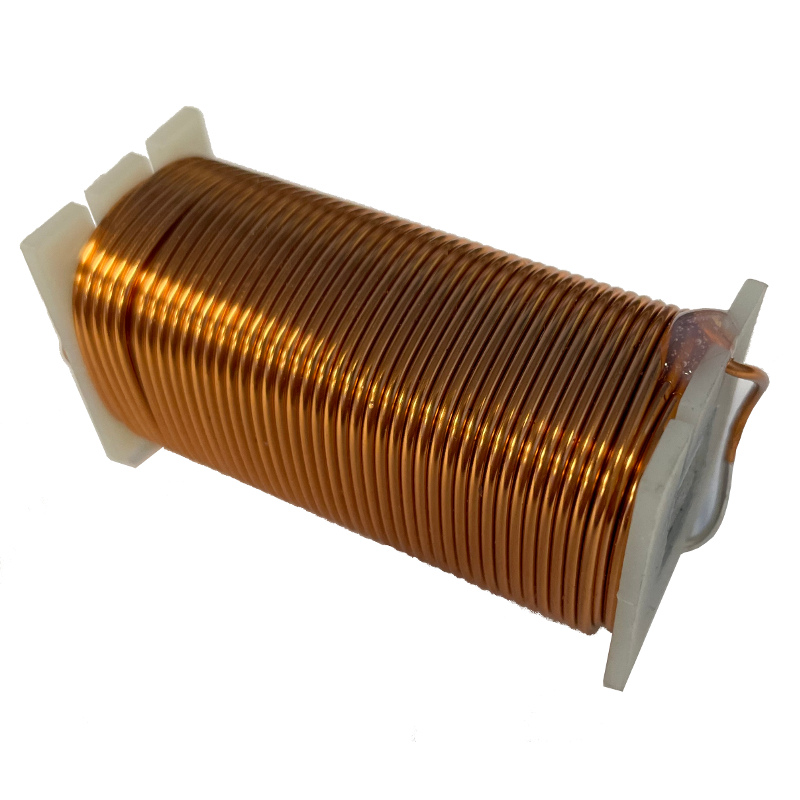

You’ve most likely seen coils of copper wire in audio filters, but what do they do? and how do they work? We’ll try to give a simple explanation here.

At the most basic level, and inductor is just a coil of wire, and the design and construction of the inductor determine it’s inductance, which is usually measured in millihenries. Larger value inductors tend to be needed for low frequency filters, perhaps as big as 4 or 5 millihenries, but much lower value inductors are needed for higher frequency audio applications, typically between 0.1mh and 1.5mH for most common 2 way crossovers.

So, how do they work? It gets a bit sciencey, so we’ll try to keep it simple. When current flows through a wire, it creates a magnetic field around the wire. When the wire is wound as an inductor, the magnetic fields from various sections of the inductor will each have an effect on other parts of the inductor, creating a electro-motive force within the wire/inductor that opposes the applied voltage to the inductor. In effect creating an electric force in the wire that’s opposite to the voltage that’s being applied. At low frequencies, the opposing force is very small, and the inductor acts just like a piece of wire. The opposing force gets bigger and bigger as the frequency goes up, and this makes it more difficult for high frequency signals to pass through the inductor. This allows a single inductor to work as a low pass filter – blocking high frequencies and letting low frequencies pass through.

All you have to do is select the correct value of inductor (in mH) for the cut-off frequency you need for your filter.

Well, if only it were that simple. You then need to decide what type of inductor to use.

Ferrite Core. For low power filters, people have often used ferrite cored inductors. The magnetic permeability of the core increases the magnetic field strength of the inductor, allowing a specified inductance to be reached with much fewer turns of wire. This has the benefit of reducing the resistance of the inductor, making it less lossy, and ensuring more of the power reaches the speaker and less is lost in the inductor as heat. Ferrite cored inductors have a problem, they will saturate at high power levels, when the maximum magnetic field strength has been reached in the core, after this the field cant continue to increase, which causes the inductance to decrease. This causes increased distortion, and is undesirable in audio circuits. Most designers avoid ferrite cored inductors for higher power circuits.

Powdered Iron Core. You could think of these as a ‘premium’ ferrite core – they have similar benefits in terms of fewer turns of wire. They offer improved power levels due to higher saturation point, but this comes at increased cost. Considered a good compromise where ferrite core is too low power, but air cored is too big and expensive.

Laminated Steel Core. Another alternative to ferrite core inductors, but suffering from similar distortion issues especially at higher frequencies, which makes them more suited to low pass filters. The saturation point is lower than powdered iron core, but they benefit from the fact that large value inductors (2mH-4mH) are possible without huge amounts of wire being used, this helps keep the size and cost manageable, and avoids losses due to resistance of the wire.

Air Core. Ask any audiophile, and just plain simple air is what’s best inside an inductor. The saturation point is typically so high you can achieve extremely high power levels without distortion from saturation. The inductor is generally unaffected by temperature changes, and the core (being air) cant rattle, vibrate or crack, and so is very stable. There is a drawback – particularly at low frequencies – in the the inductors can get quite large and expensive. The size of the inductor can mean losses in the wire, and heat build up, which are not ideal. Imagine your inductor having a resistance of 1-2 ohms when your speaker is 8 ohms – significant power loss can occur in the inductor before the power gets anywhere useful.

Its fairly common for manufacturers to mix different types of inductors in one filter according the required power handling, frequency, and price point. There will always be some compromises, but choosing the best in each situation gets the required result.